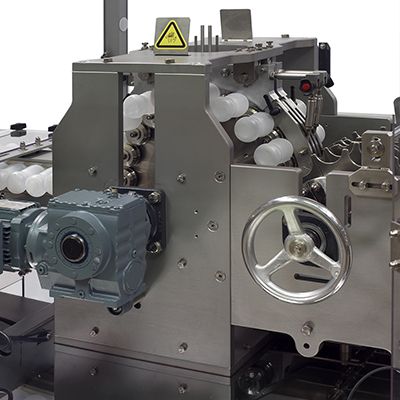

NTN Series

The NTN Series is the range of spin trimmers that allow cutting the dome shared by two bottles joined at the neck coming from the same mould, known as “Logs neck to neck” tandem bottles.

This range of spin trimmers is suitable for:

» Liquid yogurt and other dairy drinks bottled in Polyethilene bottles (PE-HDPE) commonly sold as “on the go” or “single serve” healthy drinks (i.e. bifidus, soy, muesli drinkable yogurts) on 80 ml to 300 ml capacity bottles.

» Blow moulders of all kind of bottles, as a complement of the blow moulding machine with tandem bottle cavities.

» Bottle manufacturers with IN-HOUSE blow moulding operations in the plant of the end customer.

» Blow moulding (linear or rotary) machine manufacturers.

– Through a continuous movement of both bottles, the NTN spin trimmer handles the tandem bottles in horizontal position over stationary, but adjustable, cutting blades.

– The neck of both bottles is perfectly gripped at three contact points as employed in our conventional SB Series. Neck handling allows to reach production speeds up to 30,000 logs per hour (60,000 bottles per hour) on 300 ml bottles, with total reliability and perfect cut.

– Bottle change over is fast and simple with no need of special tools.

– The lost head is deposited in a collection funnel for its transfer to the grinder.

– Uncut bottles are automatically rejected to avoid line stops.

– Trimmed finished bottles are randomly discharged through specific discharge chutes onto conveyors or bulk systems of the client.

NTN UPRIGHTER & COMBINER:

Depending on production, bottle size and bottle geometry, the NTN range of trimmers may be equipped (on option) with a bottle re-stand system that uprights and aligns bottles in vertical position, allowing to transfer them directly to the filling line.

Once the neck to neck logs are trimmed on the NTN machine, the two bottles are discharged from star-wheels to the NTN Up-righter, that re-stands bottles to a vertical position over a 2 lane conveyor belt.

A Combiner unit placed downstream the NTN bottle Up-righter will alternate the bottles from 2 rows in 1 conveyor row to convey the bottles to the leak tester or directly to the filling line.

SPECIAL EXECUTIONS:

Our NTN neck cutting technology is also available for:

– Tandem neck to neck bottles with geometry other than round (square, square-round, oval, etc).

– Trimming of neck to neck logs in vertical position, adaptable to some existing blow moulding systems.

Consult us.

MAER S.A. | La Selva, 2 Pol. Ind. de Massanes, 17452 MASSANES – Girona (España) | Tel: 972 86 42 90 | IndianWebs