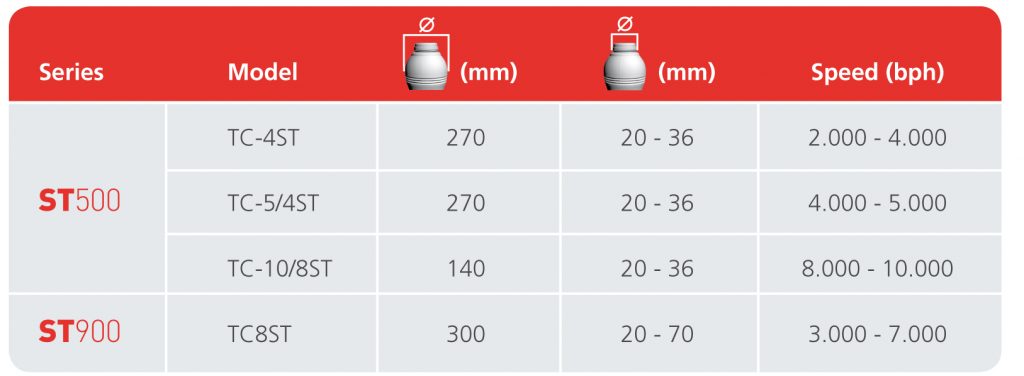

ST Series

The ST SERIES are indicated for spin trimming oval, square, rectangular handle-ware and off set neck bottles, indeed bottles that request a particular orientation (i.e. handle leading) in the production line.

They are conceived adaptaing Maer’s SB SERIES rotary trim technology to the bottle geometry and production speed of every project.

Bottle applications:

»Blow moulding of bottles for detergent and household products.

»Large volume blow moulders of bottles or those requiring to consolidate spin trimming of bottles coming from various blow moulding machines in one specific trimming unit.

»Bottle manufacturers with IN-HOUSE blow moulding operations in the bottling plant of the customer.

»Dairy processors bottling milk in Polyethilene (PE) handle-ware rectangular bottles and milk jugs that, besides efficiency, require a bottling process in ultraclean hygienic conditions. The rotary trimmer can be implemented in-line prior to or together with the filling machine, allowing the possibility of immediately fill bottles after trim (Lost head closed bottle – neck trimming – filling).

SPECIAL EXECUTIONS:

ULTRACLEAN: The ST Series may be equipped with Hepa Filter Laminar Flow Units for ultraclean applications.

ASEPTIC: An aseptic version is available. These are entirely made in stainless steel and other materials that are highly resistant to the corrosive effects of cleaning products. The aseptic version can be implemented under CIP systems and white rooms to work in synchronisation with the filling mono-block.

MAER S.A. | La Selva, 2 Pol. Ind. de Massanes, 17452 MASSANES – Girona (España) | Tel: 972 86 42 90 | IndianWebs