WM Series

MAER applies its existing trimming technology used for HDPE containers to cut off the dome of Wide Mouth jars, specially those produced with Blow-Trim technology.

Blow Trim technology allows the efficient and low cost production of wide-mouth containers by using standard narrow-neck pre-forms, eliminating expensive injection-mould tooling and saving energy, resin and cycle time.

The wide-mouth finish is built into the same bottle mould rather than into the same pre-form. The blow moulded jar has two portions: the threaded neck finish and an upper dome that has to be removed in an online process.

Our WM Series contribute to this high growth market segment offering processors low cost, unbreakable and lightweight jars as an alternative to jars made of glass.

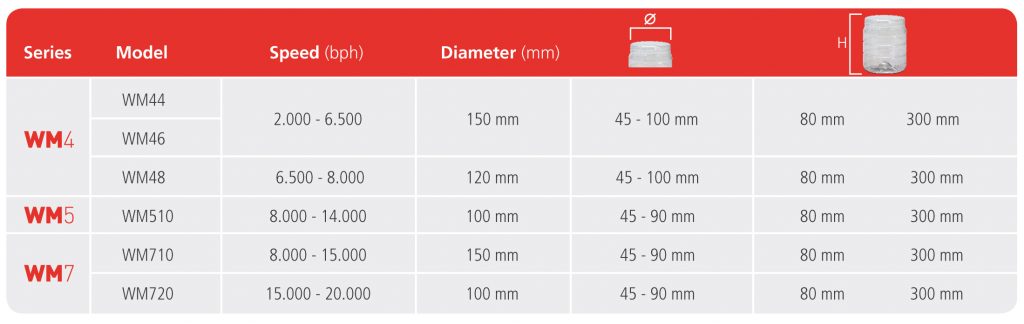

WM Series are designed in accordance with the wide mouth finish diameter and speed, processing neck diameters ranging from 45 mm up to 110 mm.

Range of equipment suitable for:

» Production of mayonnaise, sauces and solid foods (cocoa and coffee powder, snacks, cookies) in lightweight unbreakable jars as an alternative to glass.

» Large volume blow moulders or those requiring to blow Wide Mouth Jars at high speeds.

» Jar manufacturers accounting “IN-HOUSE” PET blow moulding operations in the bottling plant of the customer.

» Manufacturers of Stretch Blow Moulding and Filling equipment.

The WM Series are also applicable for trimming the dome of Wide Mouth Jars made of Polyethilene (PE) and Polypropilene (PP) materials.

MAER S.A. | La Selva, 2 Pol. Ind. de Massanes, 17452 MASSANES – Girona (España) | Tel: 972 86 42 90 | IndianWebs