Solutions for O.E.M. from Maer

Maer designs and manufactures on-line rotary bottle trimming systems for cutting the lost head of empty blow molded plastic bottles, including high speed machines with capability to reach speeds up to 60.000 bph.

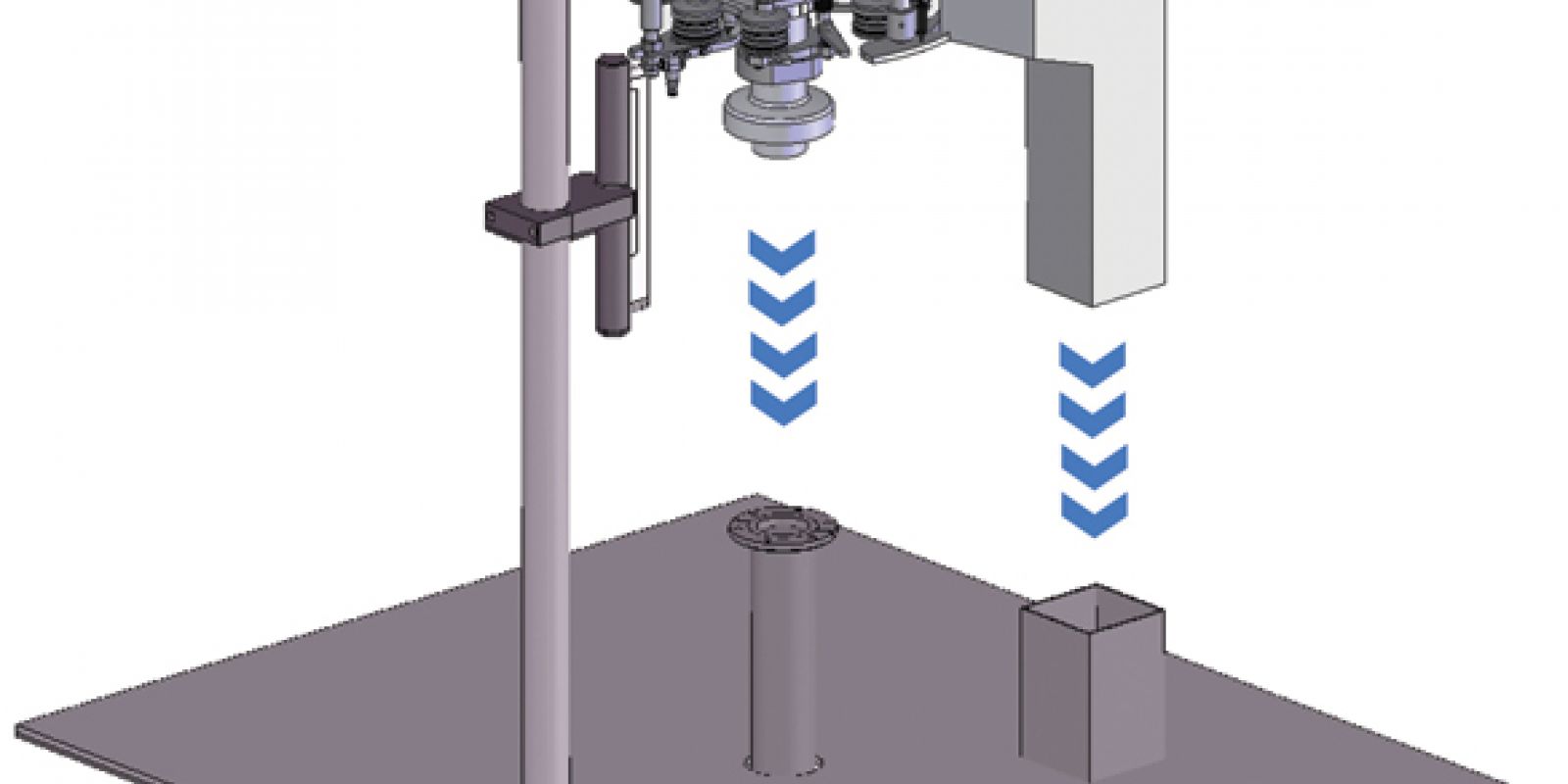

Customized trimming turrets can be manufactured for mono-block systems, allowing OEMs to integrate the lost head cutting process inside a machine performing another main operation.

The customized turret is based on Maer’s patented trimming system featuring neck handling and bottle rotation along a stationary non heated knife.

The O.E.M provides the mono-block with the drive and container handling elements necessary to feed and out-feed bottles to and from the turret.

The turret is supplied to the mono-block manufacturer duly assembled for its simple and easy integration, including:

- Carrousel with the required number of stations and the required mono-block’s bottle pitch.

- Turret height adjustment system – Manual (RM) or Motorized (RA) – to allow the accommodation of containers with different height.

- Set of bottle change parts and neck trimming tools adapted to every bottle being processed.

- Blowing pipe for the rejection of the trimmed lost heads out of the turret.

- Lost heads discharge funnel.

- Photo-eye for the detection of non trimmed bottles.

- Rejection system of non trimmed bottles (optional)

Examples of trimming turrets for mono-block applications include bottle unscramblers (1),bottle leak testers (2), bottle rinsers and, mainly, filling/sealing/capping mono-blocks for milk and drinkable yoghurt in HDPE and PP bottles (3).